Self Adhesive D Type Foam Seal Strip

Self Adhesive D Type Foam Seal Strip,self-adhesive rubber seal strip,epdm foam rubber strip,rubber foam door seal strip

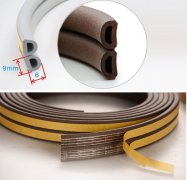

Self Adhesive D type Foam Seal Strip/Rubber Foam Seal Strip

Descriptions:

Self Adhesive D Type Foam Seal Strip Weatherbar Draft Rubber Seal

Material: EPDM, Silicone, PVC

Shape: D type foam seal strip

Length: 2.5 Meters

Color: Black, Brown, White

Dimension(approx): 9 x 6mm

Suitable gap: 2-6mm

Features:

Waterproof, Windproof, excellent aging resistance.

Easy to cut and easy to install, no requires specialist tool.

Preventing dust collection between sliding doors or windows.

Resist rain and cold wind, give you a clean and warmer environment.

Reduce the noise from outside and the sliding door slamming, give you a quiet and comfortable living environment.

Protect the window and door, reduce wear on window/door while open and close.

Perfect for doors and window frames.

Self-adhesive Rubber Seal Strip

Rubber Seal with damped, waterproof, dustproof, soundproof, insulated, fixed functions etc, are made by extruded process though high temperature microwave vulcanization, which are widely used in various kinds of industries, including auto parts, doors, windows, machines, containers and construction industries etc.

Feature

1. Good weather resistance, chemical resistance, UV resistance etc

2. Good shock absorption, waterproofing, dust prevention, sound insulation, fixing etc

Application

Self Adhesive Foam Seal Strip widely used in various kinds of industries, including auto parts, doors, windows, containers, machines, control cabinets, construction, ship industries etc.

The following is our test report from Quality Control Department.

|

Products name |

Foamed EPDM products |

||||||

|

|

|

|

|

|

|

||

|

|

number |

Test item |

|

Standard request |

result |

conclusion |

|

|

P r o d u c t

P e r f o r m a n c e |

1 |

appearance |

Qualified for test |

||||

|

2 |

Test item |

unit |

standard |

result |

Qualified |

||

|

3 |

Depending on the density |

g/cm3 |

0.65±0.15 |

0.6 |

|||

|

4 |

Tensile Strength |

MPA |

≥2.5 |

2.8 |

|||

|

5 |

Elongation |

% |

100-400 |

338 |

|||

|

6 |

|

Tensile strength |

% |

≥-15 |

-13 |

||

|

elongation |

% |

≥-25 |

-19 |

||||

|

7 |

Ozone-resisting(tear 20%,40℃/72h)

|

- |

No cracking |

No cracking |

|||

|

8 |

Brittleness temperature |

℃ |

≤-35 |

-38 |

|||

|

Conclusion |

Qualified |

||||||